Line for total heating

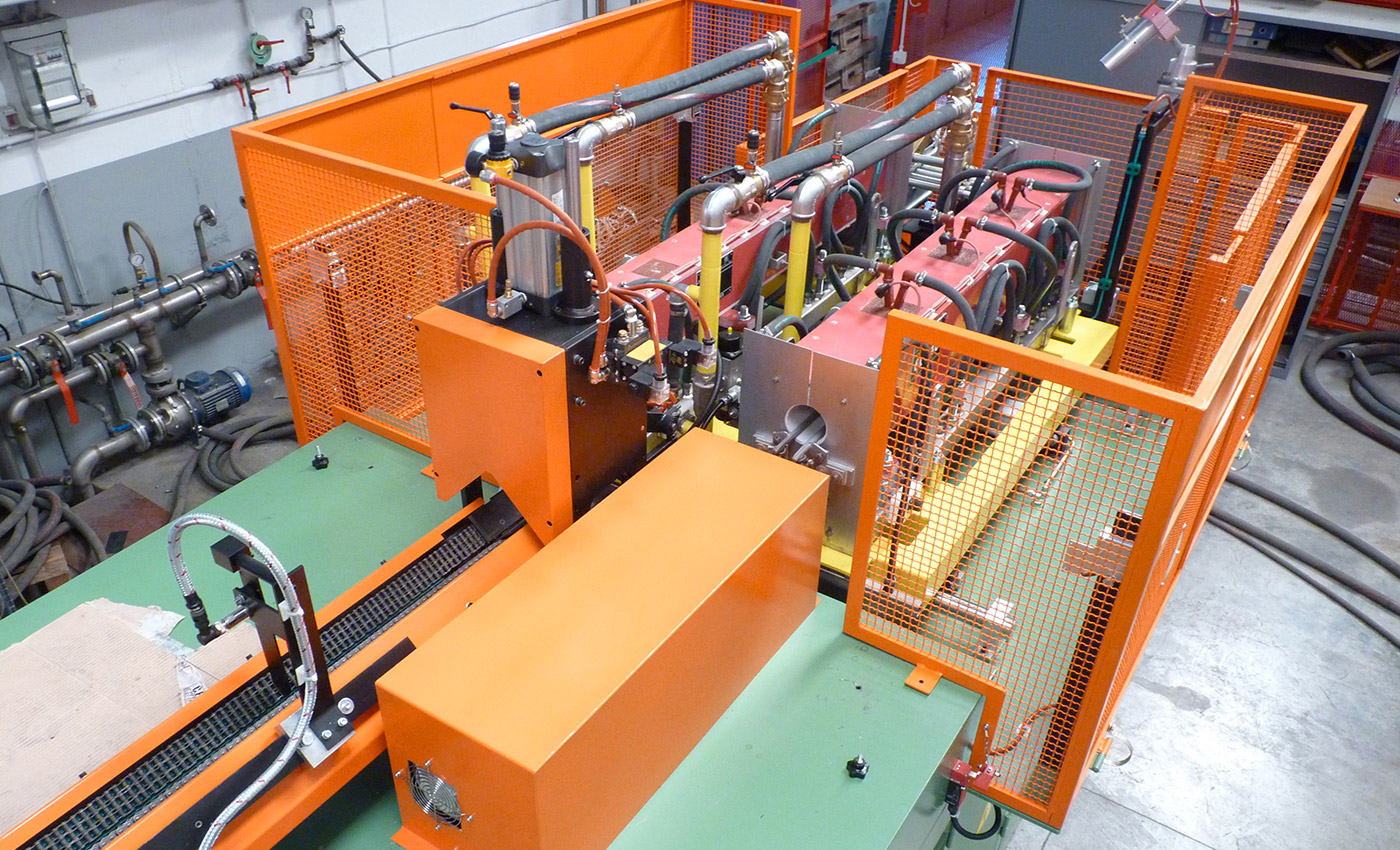

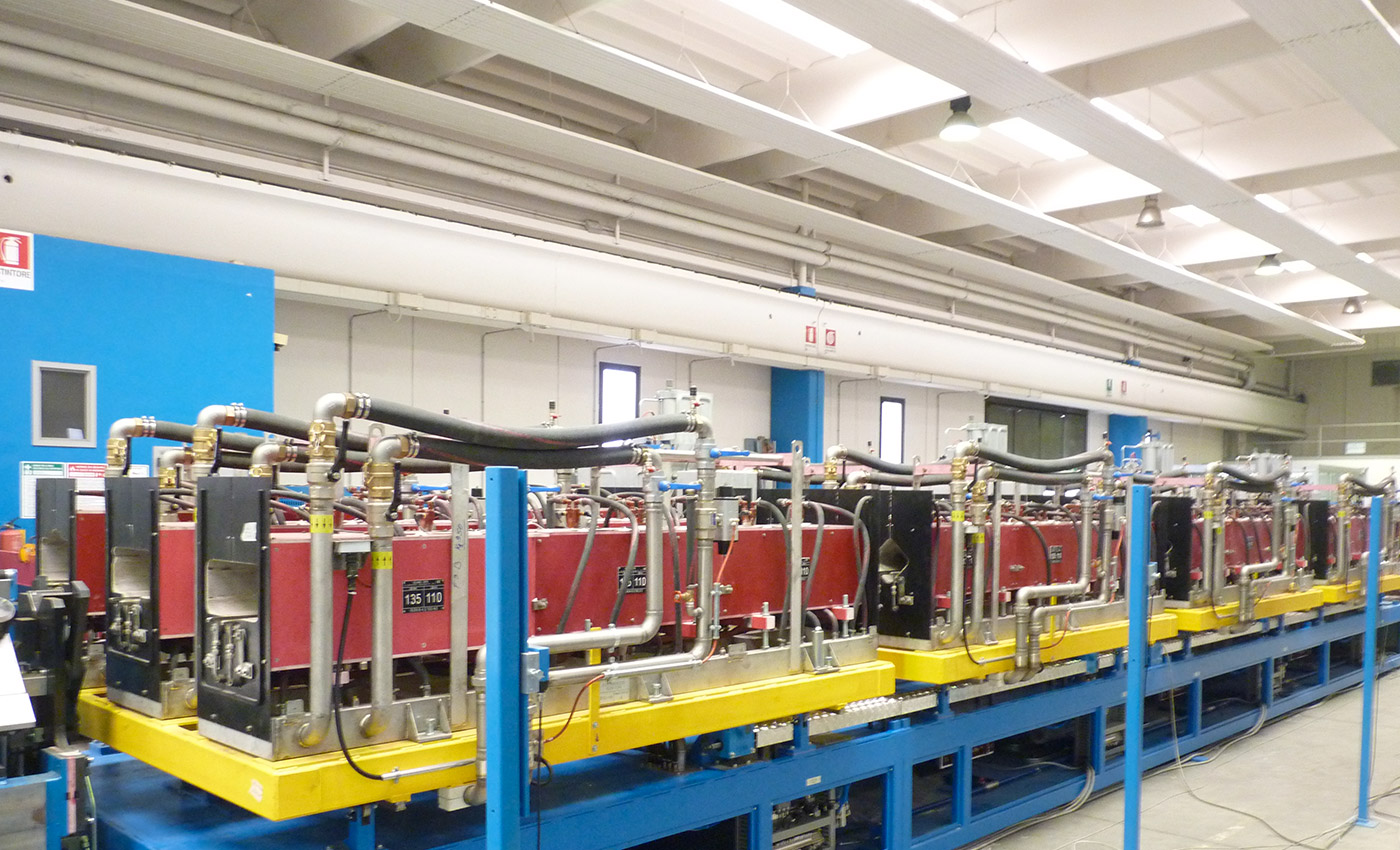

This type of equipment is destined for the heating of pre-sheared pieces of ferrous and non ferrous metals for the subsequent hot forging.

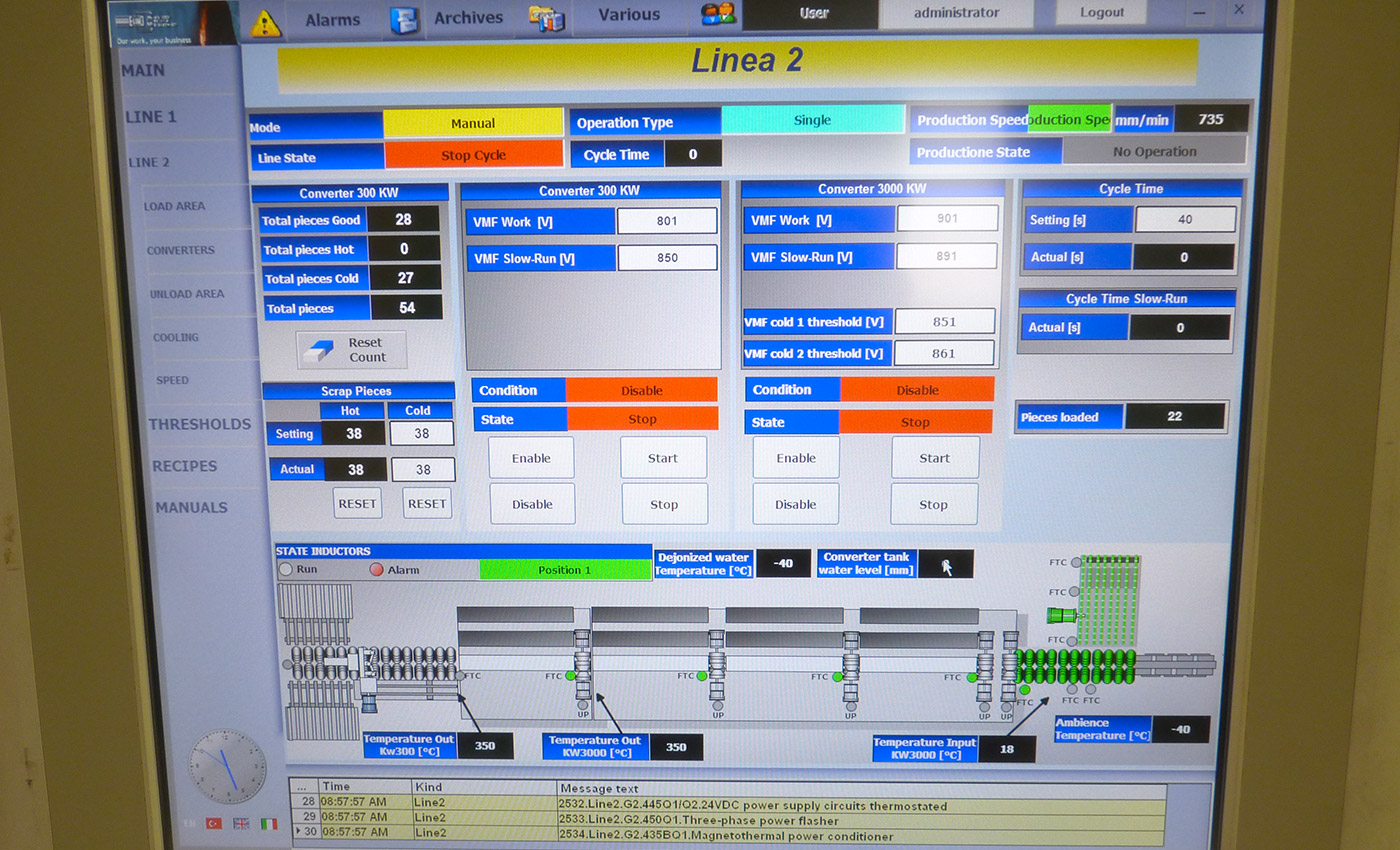

It can be equipped with wheel feeding system, track or gripper. On demand, it can be equipped with in bulk or slat automatic loader, automatic translation system of the inductors, the three-way chute system in combination with an optical pyrometer, thermoregulation system and choking system inductor reheating.

ADVANTAGES

- High efficiency: the heat develops directly into the piece by eliminating the losses related to the transfer

- Reduced spaces: allows to concentrate high power in a few meters and to avoid the storage of bars

- Immediate use: the emptying heating cycles are not necessary

- Sustainability: there are no emissions into the atmosphere

- Repeatability of the process: each piece undergoes the same treatment

- High profitability: return of investment in a very short time